Ensuring the safety of airbag systems through regular inspections is vital not just for compliance but for the protection of all users. We’re in the business of adrenaline and fun, and together let’s ensure we keep every jumper safe. Regular inspections are crucial not only for maintaining safety standards but also for preventing accidents that could result in severe injuries or worse.

The Importance of Regular Inspections:

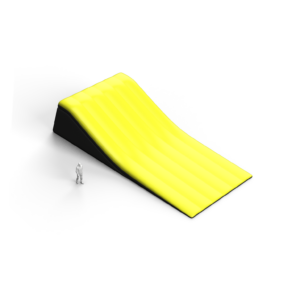

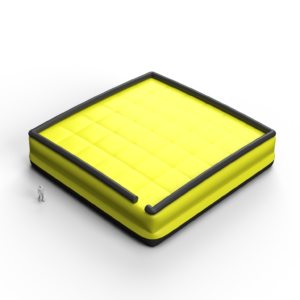

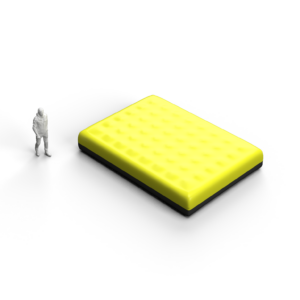

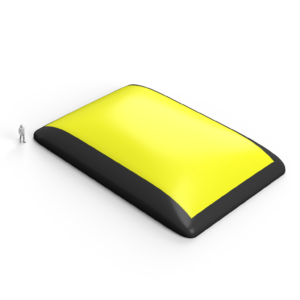

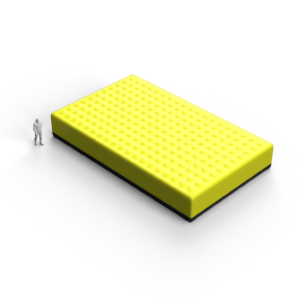

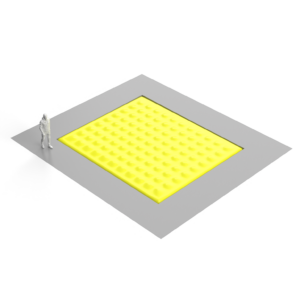

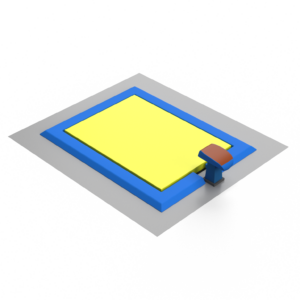

Safety is key in any activity that involves elevated risks, and an airbag is already the safer option compared to foam. We’ve implemented key elements in every airbag to ensure it’s safe for jumpers—side skirts with no jump signs that warn when the airbag is deflated, pressure alarms that sound and visually display when the pressure falls below a safe level, mounted pillars to ensure they don’t detach from regular use, and a soft touch top sheet that removes the chance of friction burn. But as a park owner, you have a responsibility to ensure your airbag system is regularly inspected to further ensure safety for every jumper.

Annual Inspections Have Multiple Benefits

Prevent Malfunctions: Regular inspections help identify potential issues before they lead to failure, such as seam tears or compromised blowers, below safe pressure within your airbag, malfunctioning side sheets, overworn pillars, which are crucial for the airbag’s performance.

Ensure Compliance: Routine checks ensure that all components of your airbag system meet the current safety standards set by governing bodies such as TÜV. Without certification, you can be liable in the event of an injury—let’s avoid this together.

Extend Equipment Lifespan: Routine inspections can significantly extend the life of your airbag by catching wear and tear early before it becomes a critical issue that can close down your airbag attraction.

Detailed Inspection Process

To understand how inspections contribute to safety, it’s essential to look at what a typical airbag inspection entails, here is a sample from the 40 point check done on your airbag:

Visual Inspections: Inspectors look for visible signs of wear and tear, checking seams, fabric, and other accessible parts for any damage.

Operational Testing: This involves testing the airbag’s blowers and if operate as expected under various conditions and can still maintain a safe level of pressure for your specific activity.

Component Checks: Detailed checks of all features of the airbag are up to a safe standard. Such as the side skirts of the bag, through to the velcro.

Airbag Report: Our team has an international standard 40-point checklist that details the health of every part of your airbag. You will receive a detailed overview following the inspection that gives you a star rating, ensuring you understand how your airbag is performing.

Onsite Repairs: Our BIG Service Crew will perform small repairs onsite such as heat welding, patching small problems, and stitching of tears. For any large maintenance that is required, our team will provide you with a report and a plan on how to complete the maintenance.

Success Stories:

We’ve helped hundreds of clients to avoid risks and we’ve also seen a few times when things didn’t go to plan. Here are a few moments when clients were happy we had been for an annual inspection:

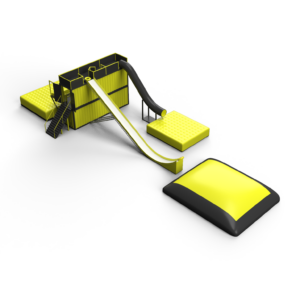

Event Disruption: At a major sports event in the FMX world, we joined for the buildup of the airbags following a long season of shipping and events the year before. We noticed some key issues in the joining of the airbags which would affect the athletes as they landed in the middle of the airbag. Our BigServiceCrew worked tirelessly the full day before the show, to fix this connection of landing airbags and ensured that all systems were functional for a packed-out show the next day, preventing what could have been a significant disruption and potential injuries during high-profile jumps. Once the event was over, we brought the airbags back to the factory to solve the problem for good.

Training Safety: Our airbags are used in a multitude of sports. During routine training sessions in a gymnastics center, a well-maintained airbag system was credited with preventing injuries when an athlete misjudged a landing. The inspected airbag performed optimally, absorbing the impact perfectly. Before the inspection athletes were touching the floor below the airbag upon their landings. Following the inspection, athletes could trust in their airbag.

The Consequences of Ignoring Maintenance:

Ignoring the need for regular airbag inspections can have some pretty heavy consequences, which we all want to avoid. We’re here to help you avoid these situations.

- Increased Risk of Failure: Without regular maintenance, the chance of malfunction increases, potentially leading to severe injuries.

- Legal and Financial Repercussions: Failure to comply with safety regulations can lead to hefty fines and legal challenges.

- Loss of Trust: Safety is critical for maintaining customer trust, especially in sports and recreation businesses. Don’t let an annual inspection be the reason for attendees losing trust in the safety within your park.

Conclusion:

Let BigAirBag help you ensure your park’s safety year after year and add a few extra years to the lifespan of your airbag. Head over to learn more about our offerings and chat with one of our team members about the best contract for you. Sign up for your annual inspection today.